Pressure Test Stands for Hydrogen (H2) Components

Pressure Cycle Test Bench | Burst Test Bench | Hydrostatic Fatigue Testing | Testing with Coolant, Oil, Water and more

Poppe + Potthoff Maschinenbau GmbH develops test systems for research & development and validation of media carrying hydrogen components. At Poppe + Potthoff we offer test stands in the field of pressure pulsation testing, pressure cycle testing, burst pressure testing and hydrostatic (fatigue) testing. The test benches are used in various component testing setups. Some examples are: shut-off valves, connection parts for containers, flexible fuel lines, non-return valves, pressure regulators, pressure reducers, pressure relief valves, flow sensors and sensors for detecting hydrogen leaks. In order to test the test parts for their design life or to find material compositions in the area of research and development, test parts are subjected to pressure tests, sometimes at ambient temperatures. Contact us today and we look forward to working on your project.

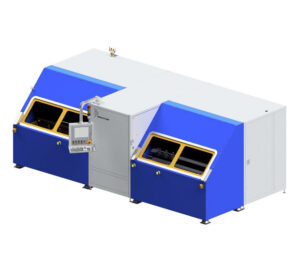

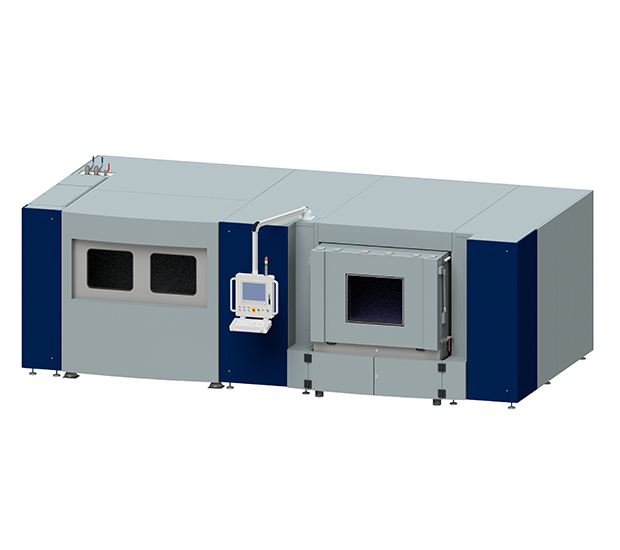

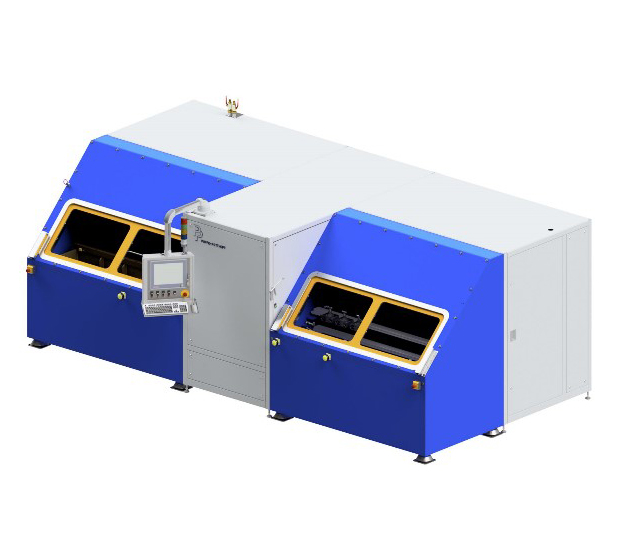

Exemplary test bench with Pressure Pulsation and a climate chamber for H2 Components at it’s core. Burst test and Hydrostatic Fatigue test capabilities can be added or purchased as stand alone test bench.

R&D Pressure Pulsation Test Stand for H2 Components up to 2000 bar

The system is a self-sufficient unit and is made of a solid welded frame, contains media preparation, a hydraulic unit and electrical engineering. The pressure test bench has a secure test chamber for burst pressure and hydrostatic pressure tests and, optionally, a climatic chamber for pressure tests with environmental simulation.

Depending on the option selected, pressure change tests up to 2,000 bar and 10 Hz can be generated. With the test circuit for hydrostatic and burst pressure tests, pressure ramps up to 3,000 bar can be generated. It is operated on a support arm PC.

For pressure tests according to EG79 / EU406 – Section 4.2

- Pressure booster for additional supply

- Displacement volume max. 15cm³

- Frequency up to 10Hz

- Pressure Load Changes as sine & trapezoidal curve (depending on the expansion volume)

- Impulse intensifier for small volumes up to 2,000bar

- Safety test chamber with automatic door

- Media treatment with dirt and clean tank

- Refill for pressure change test complete electrotechnical equipment for pressure tests

- Controller for maximum precision

- Hydraulic power pack with Moog RKP and 55kW

- Preparation for connection for second test chamber Test medium hydraulic oil

Climate Chamber

| Temperature range | -55°C…+160°C (without Climate) |

| Average rate of temperature change according to IEC 60068-3-5 | Heating ca. 2,5 K/min Cooling ca. 2,5 K/min |

| Rate of temperature change (linear) Rate of linear temperature change with test material 230 kg aluminum / steel / plastic with specific heat capacity 1.2 kJ / kg to 80% of the air temperature following without heat irradiation |

Heating ca. 1,5 K/min Cooling ca. 1,5 K/min Linear between -20°C…+135°C |

| Dimensions of the Test Chamber | 1.500 x 900 x 900 mm (H x W x D) |

| To note | The above specifications are exemplary. The chamber is specially adapted to your requirements |

Two-stage flexible pressure cycle intensifier for large volumes up to 1,200 bar

Highlights:

- Displacement volume max. 600 cm.

- Frequency up to 10Hz

- Pressure curve programable as sine & square (trapezoidal) curve

- Including extension of the hydraulic unit to 75 kW

Hydrostatic Pressure Fatigue- and Burst Test

Highlights:

- Linear pressure increases up to 3,000 bar

- Displacement volume max. 235cm³

- Variable programmable pressure ramps possible

- Pressure hold times possible

- Suitable for hydrostatic and burst pressure tests

- Including function for increased displacement

Servo low pulse pressure transducer up to 50 bar

Highlights:

- Displacement volume max. 1,500 cm³

- Frequency up to 10Hz (depending on the test volume)

- Pressure pulsation as sine & square (trapezoidal) curve

Your request

Contact us

Johannes Montag

CEO

Frank Baudler

CTO

Philip Claussen

CEO

+49 3631 46221022

salesppm@poppe-potthoff.com

Philip Claussen

Poppe + Potthoff Maschinenbau America

+1 617 250 7668

philip.claussen@poppe-potthoff.com

For further testing solutions, click the following product areas:

Poppe + Potthoff Maschinenbau is part of the Poppe + Potthoff Group

18 locations in 9 countries.

Poppe + Potthoff Gruppe has 18 production plants and sales offices in 9 countries. The name Poppe + Potthoff always indicates the highest quality – a promise to which our customers rely on, regardless of which Poppe + Potthoff location they work in.